Cleaning NS Series

The high reliable D.I. Water Scrubber system to origin Coater/Developer platform

The NS300 series is the high productivity scrubber system for 300mm wafer process based on TEL’s industry-leading Coater/Developer platform providing excellent reliability and stability. The system normally has D.I. Water brush clean and originally designed Atomized Spray(AS), bevel brush is also capable to enhance its performance efficiently. Today, in response to further device scaling and transition toward 3D-structure of semiconductor, NS300 series provides tool design flexibility for surface clean to meet process challenges ahead.

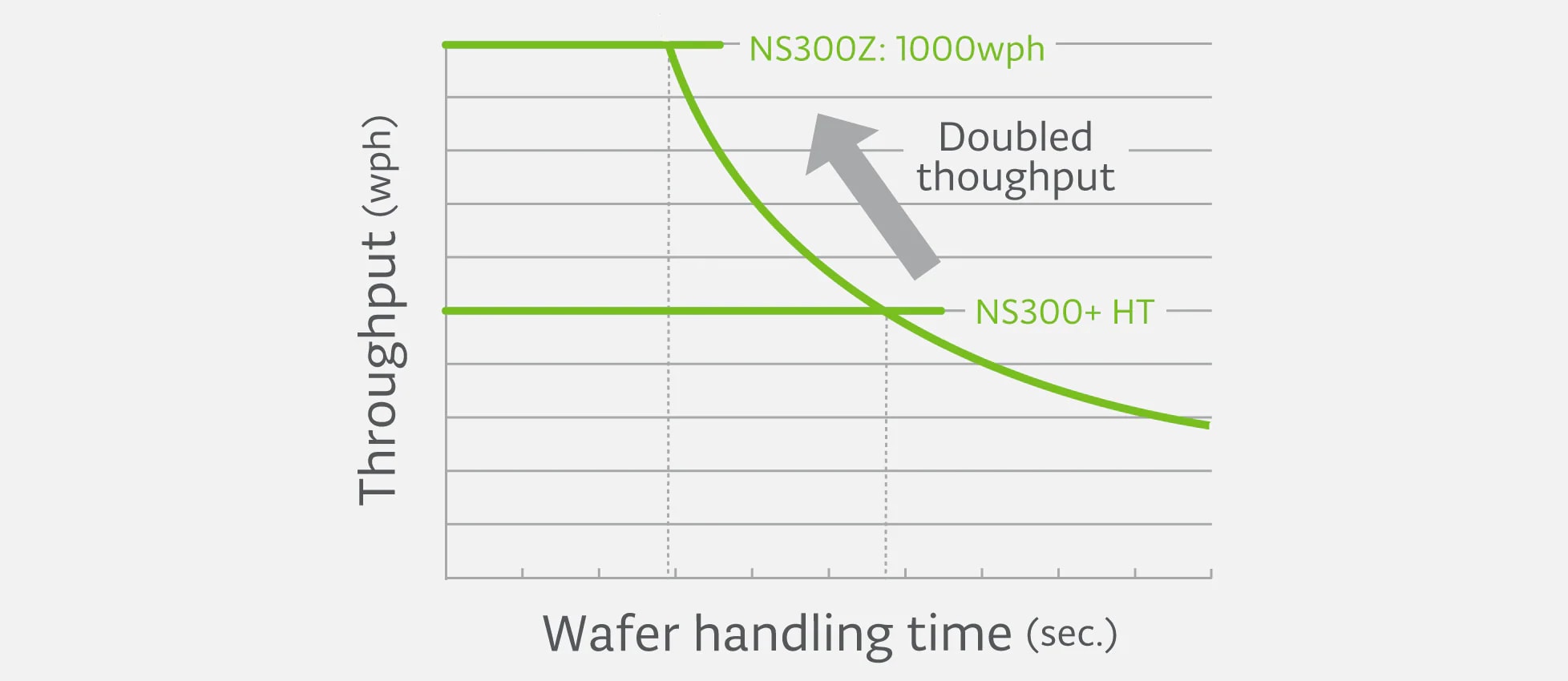

The features of the NS300+ HT process module - renowned for its reliability and stability - have been carried on into the new NS300Z, a more productive scrubber. The system has an 8-process spin chamber and achieves a throughput of up to 1,000 wafers per hour (200% of the previous system). Unique function is also equipped to realize the prevention of contamination during wafer transport, while keeping high productivity. In addition, the Atomized Spray 2 (AS2) and brushes succeeding from the previous system was improved. The NS300Z provides a wide range of scrubber clean process with high productivity even in cutting-edge device manufacturing.

NS300Z mechanical throughput

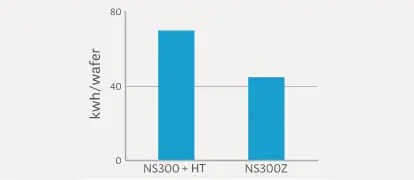

NS300Z energy reduction

The NS300+ 200mm Conversion scrubber system adopts reliable and stable process modules proven on NS300+ HT, bringing process technologies developed for next-generation 300mm devices to 200/150mm wafer scrubbing. The system can be configured with up to 8 spin modules, offering a maximum throughput of 500 wafers per hour (340% of its predecessor’s throughput) with the capacity to reliably transport various types of wafers for excellent productivity. Utilizing the Atomized Spray 2 (AS2) and brushing technologies for full recipe control, the system enables a highly productive and time-efficient scrubber clean process for legacy node devices—a product category with a growing technological demand for better stability and reliability.

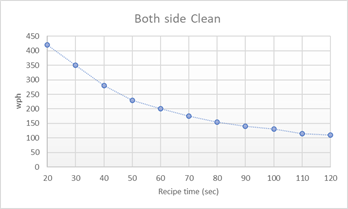

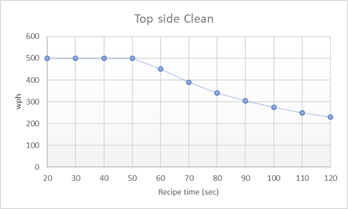

The trend of recipe time and throughput (wph)

The superior reliability and stability of the NS300+ concept has been carried on into the new NS300+ HT. It is an improved, and more productive scrubber. As with the previous system, it is equipped with an 8 process spin chamber and achieves a throughput of up to 500 wafers per hour (a more than 150% increase compared with the previous system) with a footprint equivalent to that of the previous system.

NS300 is a 300mm wafer scrubber system which enables each side of wafer surface clean with high reliability and stability. Its Atomized Spray 2 (AS2) and bevel brushes deliver high quality cleaning process by reducing surface damage during process.

Product comparison

|

|

|

|

|

|

| Wafer size (mm) |

300 | 150, 200 | 300 | 300 | 300 |

| Availability | New | New | New | New | Certified used |

| Throughput (wph) |

1000 | 500 | 500 | 320 | 180 |

| Process | DIW scrubber | DIW scrubber | DIW scrubber | DIW scrubber | DIW scrubber |

| Substrates | Si, Glass | Si, SiC Sapphire LT, LN, GaAS, etc. | Si, Glass | Si, Glass | Si, Glass |

| Dry method | Spin, N2 blower | Spin, N2 blower | Spin, N2 blower | Spin, N2 blower | Spin, N2 blower |

| Nozzle type | AS2, Brush, BVL Brush | AS2, Brush, BVL Brush | AS2, Brush, BVL Brush | AS2, Jet, Brush | AS2, Jet, Brush |

| Pertical removal performance | >95% | >95% | >95% | >95% | >95% |

Ingenio is registered trademark or trademark of Tokyo Electron Limited in Japan and/or other countries.